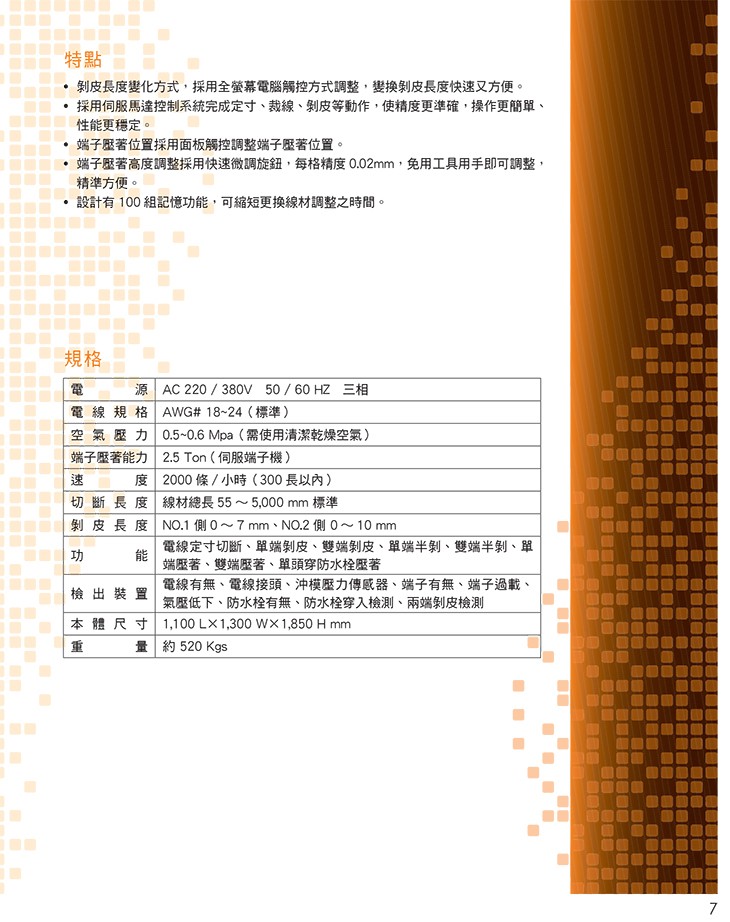

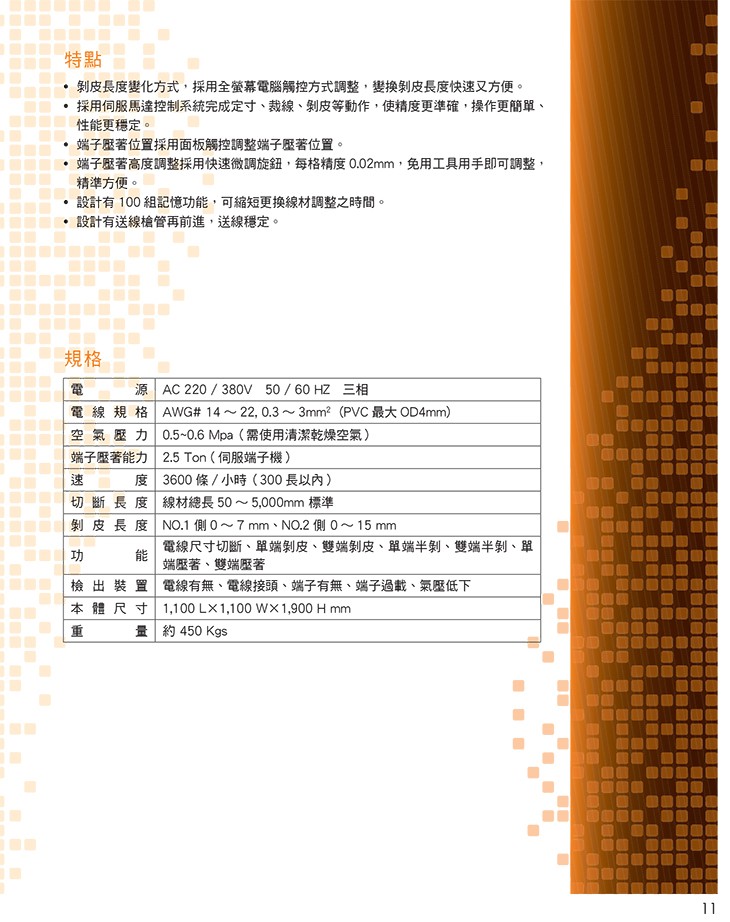

- Introduce the use of stripping tape hitting terminal machine specifications

- Why just purchased back the mute terminal machine will be fixed poorly?

- Ningbo automatic terminal machine brand

- Zhuzhou sales intelligent terminal machine

- Intelligent terminal machine

Contact Person: Miss Wang

Phone: 15999898070

Telephone: 0769-87883409

Email: cl-tk@chulun.com.tw

Address: Room 101, Building 4, No. 8 ,Qinghe Road ,Huangjiugkeng Village,Huangjiang Town, Dongguan City, Guangdong Province

Luoyang supply automatic terminal machine

Supplied in LuoyangAutomatic terminal machine

The automatic terminal machine is still a kind of mechanical product that is used more in our lives. Those who come into contact with this profession should have an understanding! Also, because this kind of product is fully automatic, the hours and minutes used are much more convenient, and the work efficiency can be improved a lot, but no matter what it is, we must learn to maintain it when we use it. If it is well maintained, then we use it. It can also extend its use time when it gets up, but what should we pay attention to when we enter the field for maintenance?

Technical features: customized vibration plate, linear vibration arrangement device, sample precision counting control device to ensure the accuracy of each bag. The packaging materials of the stripping terminal machine can be determined according to customer requirements. The machine adopts the combination of advanced step control and color code tracker to obtain perfect trademark patterns. Advanced PLC or single chip microcomputer control system, fault self-stop, self-alarm, self-diagnosis, safe and easy to use. Automatically display the number of packages, which can conveniently count the workload of the machine. Compared with ordinary terminals, automatic terminals have many advantages, and ultra-high-speed automatic terminals have more features than automatic terminals. There are three advantages here.

Luoyang supplies automatic terminal machine

Automatic terminal machine maintenance precautions

1. It is necessary for the staff to clean the machine every day to remove the dust, debris and remaining oil on the surface of the machine.

Luoyang supplies automatic terminal machine specifications and processing dimensions: the front end can be set to a length of 0.1-20 mm, the rear end can be set to a length of 0.1-9.9 mm, and the processing size is L≥60 mm , Cutting length 999999mm, cutting tolerance ±0.2mm, L=cutting length, crimping terminal: continuous terminal, crimping capacity of stripping and crimping machine standard 1.2ton, 2.5Ton, give you a PDF file format command control method: Digital control size 650mmx550mmx1210mm, weight 290kg, input power: single-phase ac200v, AC220V, ac240v50/60Hz air pressure: 17nl/min0.6mpa, power: static 300W, power/980W Processing line: applicable wire diameter: AWGᦇ12~AWGᦇ32, applicable wire :AV, AVS, AVSS, cavus, kV, KIV, UL, etc.

2. The crimping part of the automatic terminal machine must be added with butter every week, and evenly spread on the surface of the high-speed bearing and around the press block.

Talking about the functional advantages of the automatic terminal machine: The advantages of the automatic terminal machine are introduced as follows: the automatic terminal machine refers to a machine used in wire processing, also known as The automatic stripping and pressing end machine is a new type of equipment just released in recent years. It is a multifunctional machine integrating feeding, cutting, stripping and pressing ends. It is a humanized and intelligent high-end technical product, suitable for large and medium-sized , Small businesses, save labor. The advantages of the automatic terminal machine are high precision, fast speed, and have stripping, twisting and crimping detection systems. The digital control interface uses the integrated working power of light, electricity, machine, gas and magnetism, and imported electrical accessories, which are easy to operate and save time.

Striping terminal machineOperation process If the stripping terminal machine is abnormal, the power supply must be turned off immediately and the maintenance personnel should be reported to the maintenance personnel for maintenance and debugging. It is strictly forbidden for non-designated personnel to commission or disassemble mechanical parts without authorization. During the operation of the machine, it is forbidden for fingers or any part of the body to enter the movable parts or between the molds pressed by wisdom. When necessary, you must stop the stripping machine and turn off the power switch before proceeding. When two or more people are beside the equipment at the same time, one person should give command and cooperate with each other.

Luoyang supplies automatic terminal machine

3. It is necessary to add oil to the stamping guide rail of the automatic terminal machine once an hour. The smooth oiling hole is on the top of the terminal machine. It is advisable to use 2-3 drops each time. .

Luoyang supplies fully automatic terminal machine. The terminal machine refers to a machine used for wire processing. It can press five metal heads to the end of the wire and then conduct. The terminal printed by the terminal is usually for convenient connection. No welding is required, and the two wires can be connected together stably, and only need to be pulled out when disassembling. Dongguan Great Wheel Machinery Co., Ltd. has production terminal machines, you can refer to their information. When we are processing the wires, it is very troublesome if we rely on manual work. After the terminal machine is disconnected from the power supply, if the rotation has not stopped, people are not allowed at this time, so someone invented something that can help us to process the wires. Machine, terminal machine is one of them.

The daily maintenance precautions of the automatic terminal machine have been introduced here. You can learn more about it, and we should pay more attention to it when we use it. We have better assistance. We should be more careful when using the automatic terminal machine. If you need to buy automatic terminal machines, automatic pipe cutting machines, corrugated pipe cutting machines and other mechanical equipment. Contact us by phone, and we also have punctured terminals, terminal molds, terminal copper strips and other accessories. If you need them, please contact us by phone.

In the past five years, Luoyang supplies fully automatic terminal machines with a (silent) terminal machine with a server. Its operating principle is different from the above, except for the server. Information, this information is then sent to the motor, and it becomes an action. Fully automatic terminal machine: As long as the wire is put on, the terminal mold is set up, and the parameters are set in the screen, it can be produced. Terminal machines can be classified into pneumatic terminal machines, terminal machines, ultra-quiet terminal machines, automatic terminal machines, continuous terminal cutting PIN machines, even stripping terminal machines, semi-automatic ultra-quiet terminal machines, wire stripping and terminal machines, terminal blocks Machine, stripping machine, small diamond terminal machine, series motor stator terminal machine, computer wire automatic stripping machine, pin terminal machine, gold wire terminal machine, etc. Pressed terminal

Luoyang supplies automatic terminal machine

Luoyang supplies automatic terminal machine

What is the technological process of Luoyang supplying automatic terminal machine and automatic terminal machine? Turn on the power switch of the automatic terminal, and the power indicator light is on. Pay attention to whether there are obvious abnormal noises inside and outside the machine. If the operation is suspended, ask the maintenance personnel to determine whether maintenance is required. Knife selection and installation: operated by designated personnel. Before installing the tool, you need to manually compare whether the selected tool matches. The tool can only be installed after the comparison is correct. After installing the tool, it must be tested manually. First, turn off the power of the automatic terminal machine, press the down touch button, and use the dedicated board to manually move the master and slave wheels to greatly increase the punching stroke of the smart terminal press. If the hand does not move, consider whether the pressure is too high or there are other problems, check and adjust to normal. Before operation, check and confirm that the locking screws are not loose.

-

2021-07-23 15:23:28Why just purchased back the mute terminal machine will be fixed poorly?

-

2021-07-23 15:24:15How should the automatic terminal machine maintenance?

-

2021-07-24 15:38:30Suqian professional manufacturing computer wire cutting machine

-

2021-07-24 15:54:45Luoyang supply automatic terminal machine

-

2021-07-24 15:15:48Automatic terminal machine

-

CL-950L Super High Speed Automatic Computerized Wire Cutting Machine

-

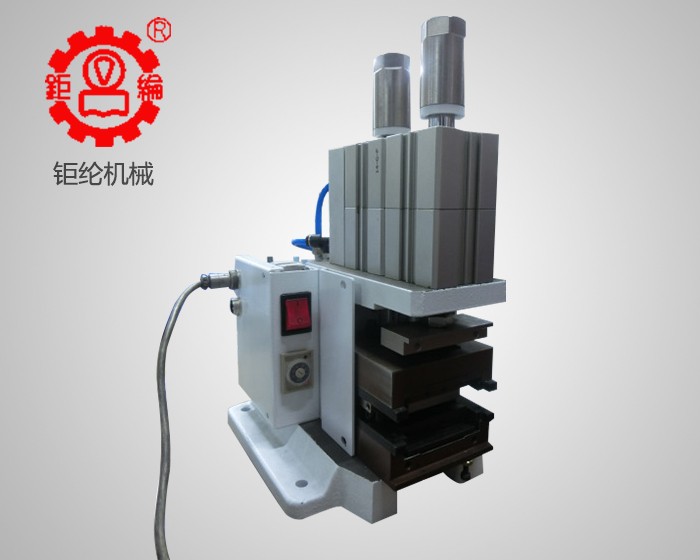

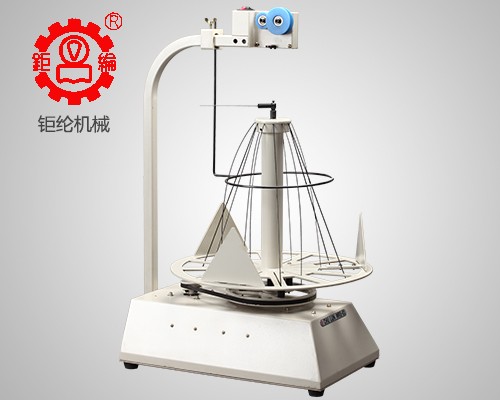

CL-RSB Automatic Terminal Crimping Machine (single head thick wire)

-

C3-5.0A CNC type silent terminal machine (5T)

-

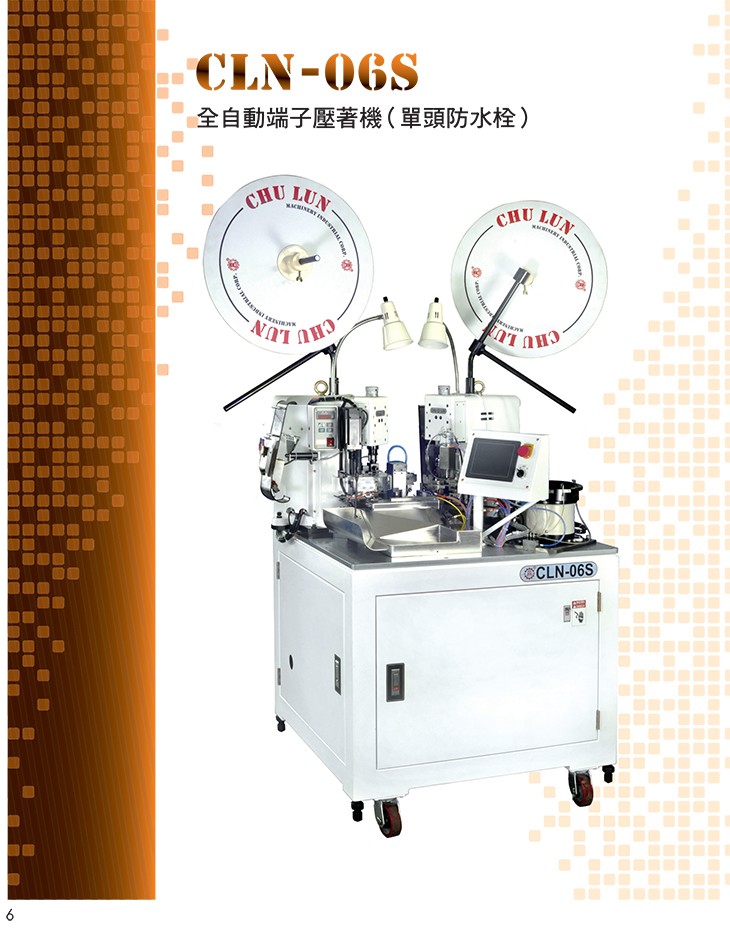

CLN-06 Automatic terminal crimping machine (thick wire)

-

C1-3.0A Terminal Machine

-

CLN-05-CH Automatic Automatic Termination Solder Dipping Machine

-

CL-540+170 Automatic Computerized Wire Cutting Machine

-

WRS-03 Restore Type Wire Discharge Machine

EN

EN

CN

CN

QQ customer service

QQ customer service