- Erdos terminal machine for sale

- Huzhou automatic terminal machine processing factory

- Causes of poor contact with the silent terminal machine?

- Which stripping tape hitting terminal machine manufacturer direct

- Terminal machine should pay attention to the use of matters

Contact Person: Miss Wang

Phone: 15999898070

Telephone: 0769-87883409

Email: cl-tk@chulun.com.tw

Address: Room 101, Building 4, No. 8 ,Qinghe Road ,Huangjiugkeng Village,Huangjiang Town, Dongguan City, Guangdong Province

Ningbo automatic terminal machine brand

Fully automatic terminal machine is a more convenient machine, we should also know this, fully automatic mechanical equipment Those with greater help can save a lot of labor and increase the output of the factory. It can also help the factory to temporarily relieve the problem of not being able to find workers. However, we are also using the fully automatic terminal machine when we use it. There will be a problem. Some time-division automatic terminal machines will have relatively loud noises after being used for a period of time. We should all be aware of this!

Ningbo automatic terminal machine brand

The stripping terminal machine can only install the knife after the comparison is correct. After the knife is installed, it is necessary to use a hand test. First, turn off the power supply of the terminal crimping machine and press the adjust button. Use a special wrench to swing the main and driven wheels to make the punching stroke of the terminal crimping machine larger. If the hand does not move, consider whether the pressure is too large or other questions, and check and debug to OK. Before operation, check each locking screw and confirm that there is no looseness. 4. Loading: Install the required terminal, use the hexagonal wrench to adjust the feed plate, so that the terminal can pass through easily, visually check whether the feeding position is suitable, if not, adjust it, use the hexagonal wrench to loosen the feeder Tighten the screws,

The length of the wire cut is inconsistent. A: The wire feed wheel is pressed too tightly or too loosely. Countermeasure: Adjust the straightening machine so that it can be straightened and sent out smoothly. There are two differences between professional production of terminal machines and automatic terminal machines. The first is the characteristics of the automatic terminal machine: the automatic terminal machine is an automatic machine that integrates wire feeding, wire cutting, stripping, terminal punching and other chemical machinery. The automatic terminal machine was developed and manufactured in Japan as early as, the operator only needs to touch the screen button to send information to the server, and then to the motor. The fully automatic terminal machine can complete all actions such as wire feeding, wire cutting, stripping, and terminal tapping within one second. Professional terminal machine molds will encounter those problems. The guide plate is not smooth, the cutter is not clean, the feed is not allowed, and so on. Hello everyone, I am doing mold maintenance and management. Now I am doing mold maintenance for terminal machines. What are the issues that need to be paid attention to when maintaining molds? Thank you? Do not remove the tools for maintenance of the mold, which is a waste of time. Need to pay attention to the following points: 1. Use an air gun to clean up the remaining copper scraps inside and outside the end mold. 2. Check whether each screw is loose. 3. Check whether the tool is worn or broken.

Poor peeling of the stripper and terminal machine: the peeling time varies. There are many reasons for different stripping lengths. The common stripping length is too tight or too loose. At this time, it is only necessary to properly adjust the open space between the two wheels until the wire cannot be pulled by hand. On the other hand, this may be a problem with the blade. The blade is cut too deep or too shallow, and even the blade is installed at an angle, which may also cause this result. At this time, it is necessary to adjust the position of the blades as needed. If it is caused by damage to the blade, it is recommended to replace the blade immediately. Inconsistent cutting lengths Inconsistent cutting lengths may be due to blade or blade wear; to encounter such a problem, simply replace the cutter with a new one.

As a humanized and intelligent high-end technology product, the automatic terminal machine is suitable for large, medium and small enterprises that need to use wire harnesses. It can save a lot of labor and is efficient Several times the semi-automatic terminal machine.

Stripping and tapping terminal machineTighten the round nut after adjustment. Safety inspection of Julun automatic terminal machine before operation: confirm that the wrench has been removed. Tighten the round nut after adjustment. Julun automatic terminal machine works normally: Press the operating switch to the working position, the motor starts to run, and the wire is placed in the proper position of the terminal crimping position (the crimped terminal must be in the middle of the upper and lower die cutters). Step on the foot switch, the main unit slides down, complete the crimping of the wire and the terminal, and send the next terminal to the crimping position. Repeat the above steps to achieve continuous crimping between the wire and the terminal.

Ningbo automatic terminal machine brand

Generally, it is normal to have fine noise. If it is a loud one, then there are these two problems, a. There is abrasion between certain parts and components of the terminal machine, which leads to increased conflicts; b. The screw of the terminal machine is loose during work, causing the parts to vibrate and become rugged.

Full-automatic parallel wire terminal machine. (It adopts PLC or single-chip control, servo motor or stepper motor to provide power. The production process does not require manual participation, and the production efficiency is high. This type of domestic equipment can realize about 7000pcs of wire cutting per hour and 11000pcs of terminal crimping. The mid-term is 3500pcs. Parallel wire crimping terminal, 7500pcs is a single wire crimping terminal, which can automatically detect the crimping quality of the terminal. It has the functions of the above three automatic terminal machines. It is currently one of the professional terminal machines with a very good degree of automation in the domestic market)

Ningbo automatic terminal machine brand

The working principle of the semi-automatic terminal machine, the diagram is to put the qualified terminals on the terminal frame according to the requirements, and install the terminal chain head into the equipment according to the correct method. Recognize the equipment knife mold Match with the installed terminal, then adjust the pressure and other parameters of the pressure monitoring, and adjust the corresponding position of the terminal chain and the device. Take the stripped wire and check for defects, then align the wire with the slot of the terminal machine and the terminal opening, adjust the position, and then step on the foot pedal with your foot to put the terminal on the wire.

The development of professional terminal machine: how to install the automatic terminal machine? Put the qualified terminals on the professional terminal rack as required, and install the terminal chain head into the equipment according to the correct method. Confirm that the die of the equipment matches the installed terminal, then adjust the pressure and other parameters of the equipment, and adjust the corresponding position of the terminal chain and the equipment. Take the stripped wire and check for defects, then align the wire with the slot of the terminal machine and put it in the terminal opening, adjust the position, and then step on the pedal with your foot.

Ningbo automatic terminal machine brand

Applying the inner cavity shape can make the blank obtain the corresponding three-dimensional shape. The mold generally includes two parts: a movable mold and a fixed mold (or a convex mold and a concave mold), which can be separated or combined. The parts are taken out when they are separated, and the blanks are injected into the mold cavity to form when they are closed. The stripping terminal machine mold is a precision tool with a complex shape that can withstand the expansion force of the blank. It has high requirements for structural strength, rigidity, surface hardness, surface roughness and processing accuracy. The development level of mold production is at the level of mechanical manufacturing. One of the important signs.

Ningbo automatic terminal machine brand

Introduction to the working principle of the professional terminal machine: Terminal machine refers to the machine used for wire processing, which can press the hardware head to the end of the wire. Then do conduction. The terminal produced by the terminal machine is usually for more convenient connection, and the two wires can be connected together stably without welding. And only need to unplug the power plug when disassembling. What is the working principle of the professional terminal machine? 1. (Stepping principle) The motor keeps rotating. There is a circuit breaker in the clutch, and each action is a standard "O", which is very common. 2. In the past five years, there was a (silent) terminal with a server. Its working principle is different from the above. It just sends a message to the server and then transmits it to the motor to perform the operation.

-

2021-07-23 15:22:40Mute terminal machine non-normal stop causes

-

2021-07-24 14:16:00Foshan automatic terminal machine wholesale price

-

2021-07-23 15:24:15How should the automatic terminal machine maintenance?

-

2021-07-23 17:01:46Huzhou automatic terminal machine processing factory

-

2021-07-24 14:06:14Maoming stripping tape hitting terminal machine manufacturer

-

WRS-04+05 Shaft loading type wire release machine + wire feeder

-

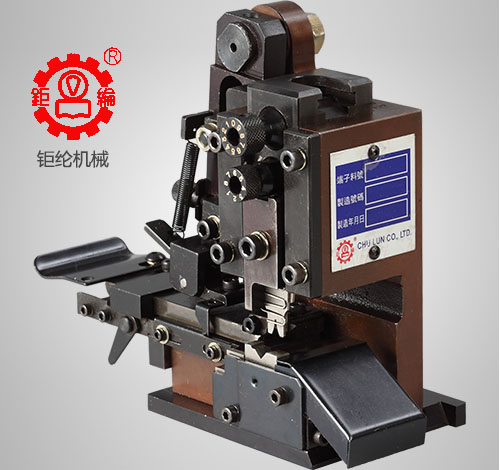

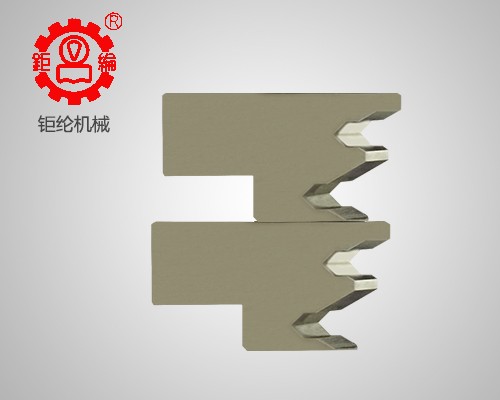

CN peeling knife

-

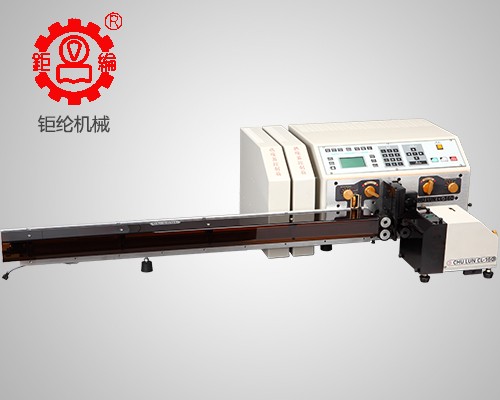

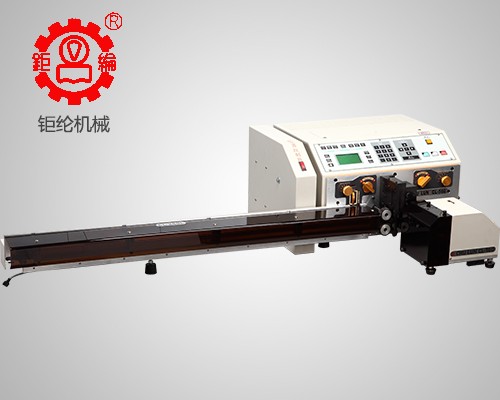

CL-560+160+260L Automatic Computerized Wire Cutting Machine

-

CLM-6 card die

-

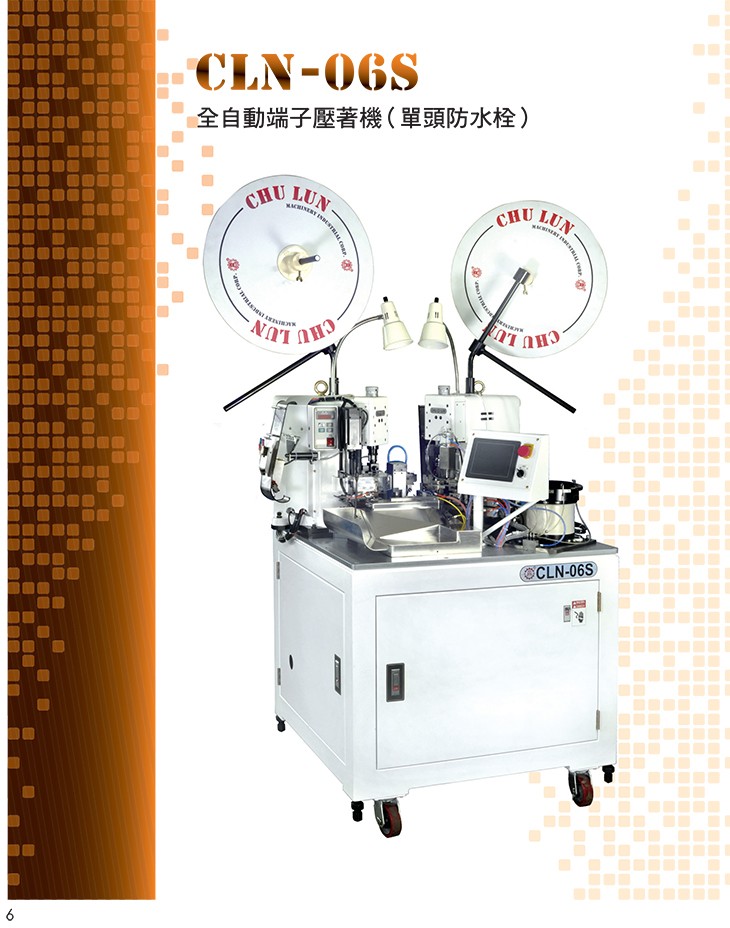

CLN-06S Automatic Terminal Crimping Machine (Single Head Waterproof Plug)

-

CL-RSB Automatic Terminal Crimping Machine (single head thick wire)

-

Special cutting knives

-

CL-FSH Hanging pressure detector

EN

EN

CN

CN

QQ customer service

QQ customer service